Global Solutions

Shared with

Responsibility

“The one that could only be achieved with the backing of a truly international group, It’s with the support of the group in its technology and its development and its ongoing innovation that makes the mission possible.”

— Stephen Davies, the Commercial Director for RIIFO UK

Global Capability

With outstanding products, customer-oriented services,

and efficient marketing strategies, RIIFO has become a

well-known market leader around the world.

Global Capability

With outstanding products, customer-oriented services,

and efficient marketing strategies, RIIFO has become a

well-known market leader around the world.

Distributors Worldwide

Projects Serviced

Employees

Branches & Subsidiaries

System

Plumbing

RIIFO Plumbing Systems specializes in Multilayer Plumbing, PPR Plumbing, and PEX Plumbing Solutions, providing optimized, hygienic, and reliable water supply systems for a global market.

System

Heating & Cooling

RIIFO Heating and Cooling System includes Underfloor Heating and Air Conditioning Piping. Both are easy-to-install, flexible, energy-efficient, and cost-effective solutions designed to enhance indoor comfort and climate control.

System

PVC Electrical Conduit

RIIFO PVC Conduit System ensures reliable electrical safety, durable construction for cost savings, and is recognized by the international environmental standard EPD.

System

PVC Drainage

RIIFO PVC Drainage System features an exceptionally smooth inner wall, increasing drainage speed by 30% compared to common iron pipes of the same diameter.

System

Multilayer Gas

Combining the strengths of both plastic and metal pipes through a 5-layer design, RIIFO Gas Piping System offers enhanced performance, effectively minimizing the risks of gas leakage and fire hazards.

System

HDPE Infrastructure

RIIFO Infrastructure System utilizes a state-of-the-art plastic pipe material primarily composed of high-quality polyethylene resin.

System

Plumbing

RIIFO Plumbing Systems specializes in Multilayer Plumbing, PPR Plumbing, and PEX Plumbing Solutions, providing optimized, hygienic, and reliable water supply systems for a global market.

System

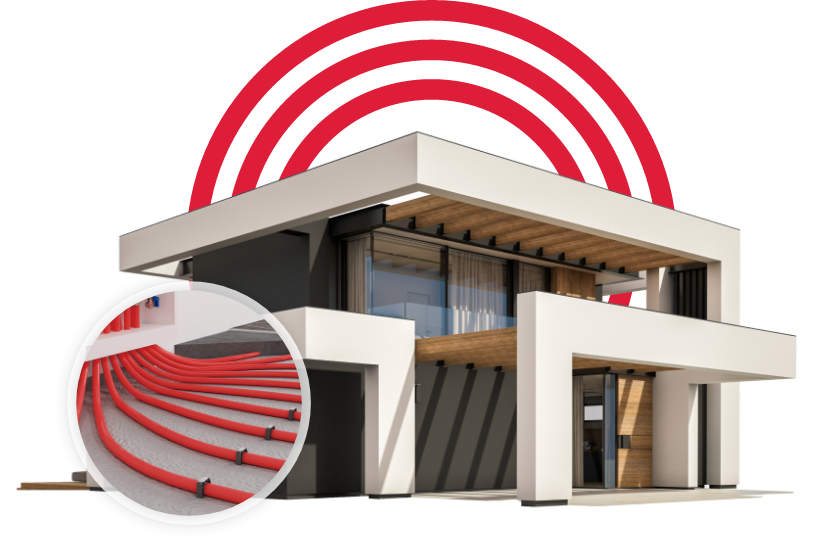

Heating & Cooling

RIIFO Heating and Cooling System includes Underfloor Heating and Air Conditioning Piping. Both are easy-to-install, flexible, energy-efficient, and cost-effective solutions designed to enhance indoor comfort and climate control.

System

PVC Electrical Conduit

RIIFO PVC Conduit System ensures reliable electrical safety, durable construction for cost savings, and is recognized by the international environmental standard EPD.

System

PVC Drainage

RIIFO PVC Drainage System features an exceptionally smooth inner wall, increasing drainage speed by 30% compared to common iron pipes of the same diameter.

System

Multilayer Gas

Combining the strengths of both plastic and metal pipes through a 5-layer design, RIIFO Gas Piping System offers enhanced performance, effectively minimizing the risks of gas leakage and fire hazards.

System

HDPE Infrastructure

RIIFO Infrastructure System utilizes a state-of-the-art plastic pipe material primarily composed of high-quality polyethylene resin.