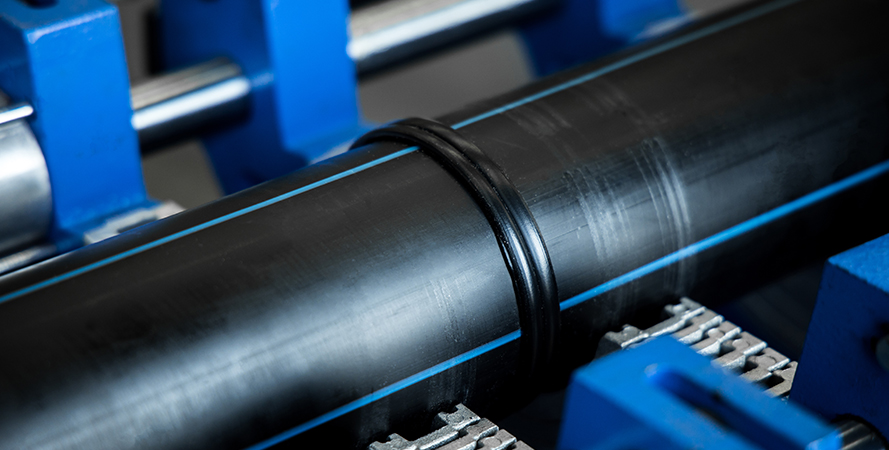

Infrastructure- HDPE Infrastructure System

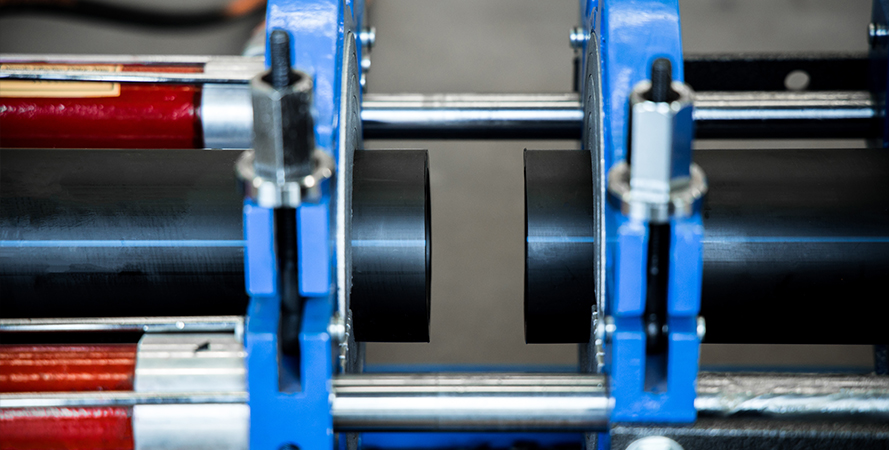

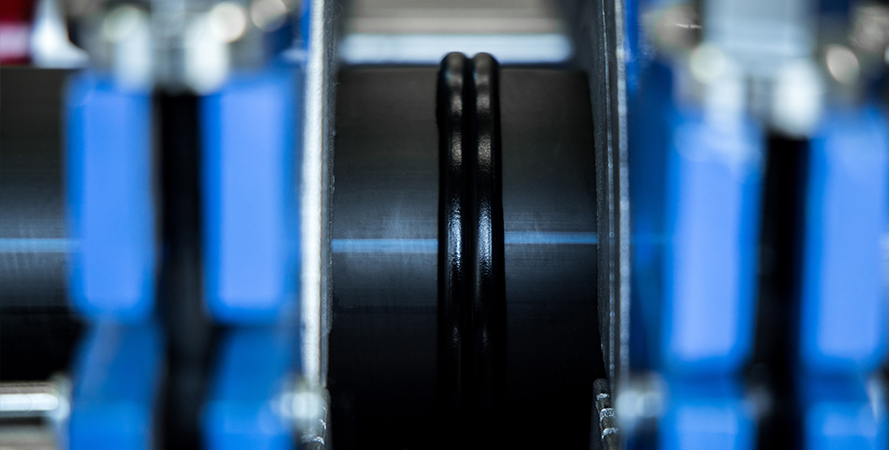

Butt-fusion

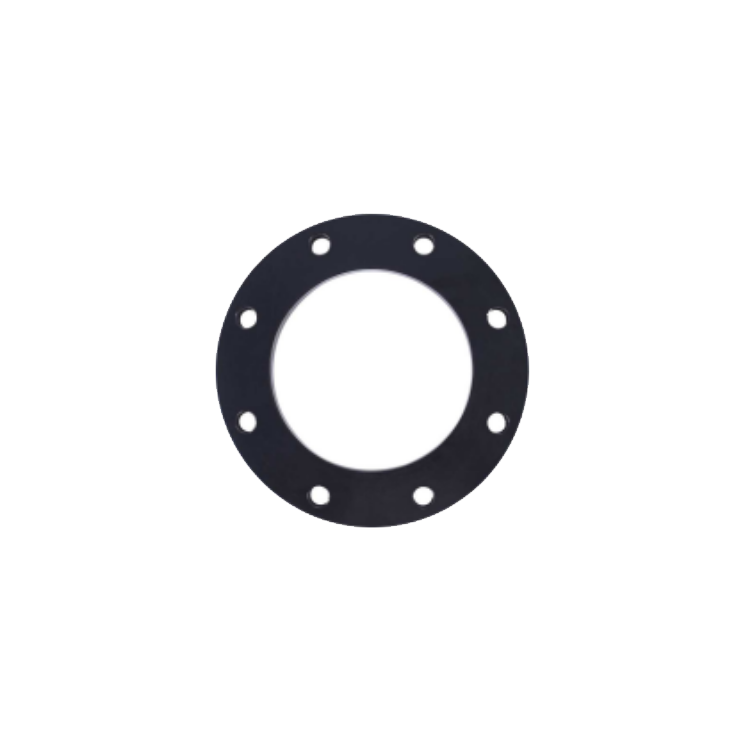

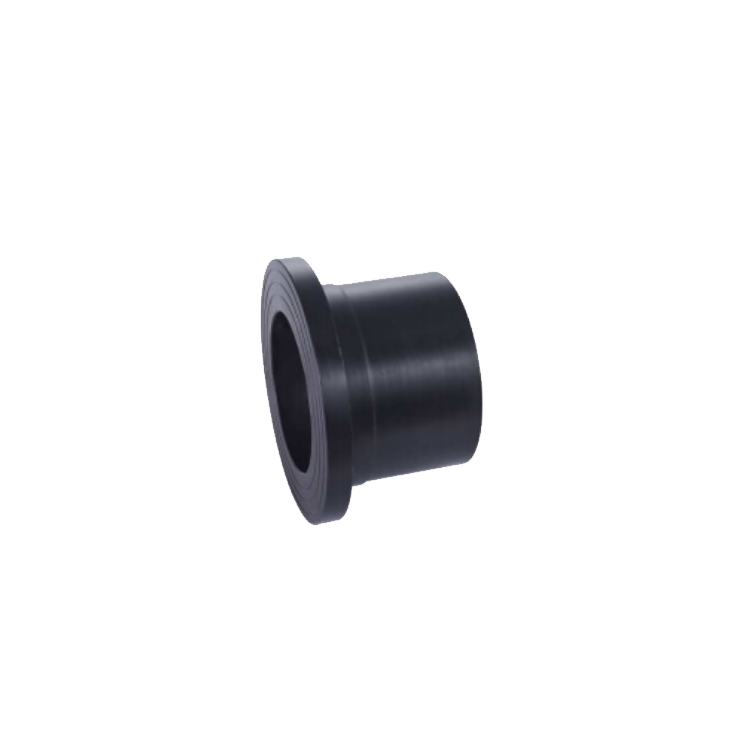

Welding Fitting

The connection of the pipe and fittings can be installed with butt welding, hot-melt socket and electro fusion. The entire piping system that has been widely used in municipal projects is safe, reliable and low-cost.

Service life:50 years

Non-toxic hygiene: no heavy metals, materials can be recycled

350% pipe elongation resist uneven settlement of foundation

Connecting is convenient and reliable with various construction methods

Aging resistance, black pipe can reduce the ultraviolet light on the pipe.

Excellent low temperature impact resistance performance

Butt-fusion Welding Fitting