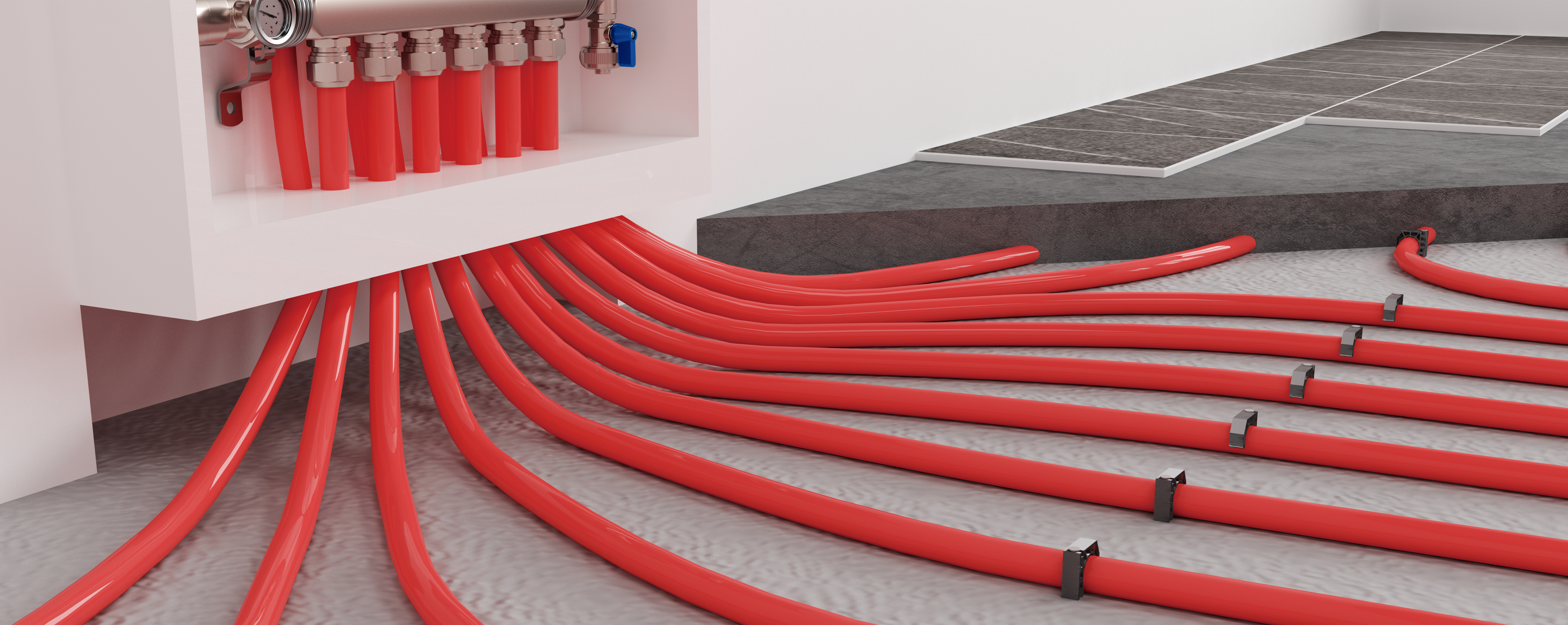

Selecting the right piping material for underfloor heating (UFH) systems requires careful analysis of thermal conductivity, flexibility, and durability. Materials such as PERT and PEX provide distinct advantages. PERT offers superior thermal conductivity and flexibility, while PEX boasts high resistance to temperature fluctuations. Installation practices significantly influence performance as well. Factors such as bore sizing accuracy and insulation must also be considered. Understanding these elements can guide effective decision-making for optimal UFH system performance. Additional insights follow.

Key Takeaways

- Choose materials with high thermal conductivity, like PERT, for efficient heat distribution in underfloor heating systems.

- Consider flexibility for installation; PEX and PERT offer advantages in complex layouts.

- Assess pressure ratings and temperature ranges; PERT supports up to 6 bar at 70°C, while PEX provides high resistance to fluctuations.

- Evaluate durability and chemical resistance; PPR and multilayer pipes enhance longevity and performance in different environments.

- Factor in warranty coverage and cost trade-offs; investing in higher-quality materials can justify long-term reliability and efficiency.

Introduction

The increasing adoption of underfloor heating (UFH) systems in both residential and commercial sectors underscores the importance of selecting appropriate piping materials. The choice of pipe material substantially impacts system efficiency, user comfort, and the longevity of the heating installation. Understanding the characteristics and performance of various pipe types is essential for optimizing the overall effectiveness of UFH systems.

Rising popularity of underfloor heating (UFH) in residential and commercial spaces

How has underfloor heating (UFH) gained traction in both residential and commercial settings? The adoption of UFH systems is increasing due to their efficiency and comfort, particularly as energy consciousness rises. Homeowners and businesses alike are drawn to the aesthetic appeal and space-saving benefits of UFH. As a result, debates around energy efficiency and environmental sustainability have become prevalent in construction discussions.

| Aspect | Residential Benefits | Commercial Benefits |

| Aesthetic Appeal | Eliminates visible radiators | Maximizes usable space |

| Energy Efficiency | Lower utility costs | Reduced operational expenses |

| Comfort | Even heat distribution | Enhanced employee productivity |

| Installation | Flexible design options | Quick installation timelines |

| Maintenance | Minimal upkeep | Reliable long-term solution |

Such advantages contribute to the rising popularity of UFH despite occasional topic irrelevance in traditional heating discussions.

Why pipe material choice determines system efficiency, comfort, and longevity?

Which factors influence the efficiency, comfort, and longevity of underfloor heating systems? The selection of pipe material is critical, as it directly affects pipe durability, thermal conductivity, and resistance to deformation. For instance, PEX-a and PERT-AL-PERT pipes offer superior flexibility and heat distribution, enhancing system efficiency. Installation rituals also play a pivotal role; improper handling can lead to kinks or leaks, undermining performance. Additionally, cost considerations often dictate material choice, with cheaper options potentially sacrificing longevity and efficiency. Environmental impact and compliance with local regulations further complicate decisions, necessitating a balanced approach. Ultimately, a well-chosen piping material not only maximizes heating performance but ensures lasting comfort and reliability.

Understanding Underfloor Heating Systems

What factors contribute to the effectiveness of underfloor heating systems? Key elements include the quality of flexible fittings, the precision of bore sizing, and the efficiency of heating system controls. Proper pipe insulation minimizes heat loss, ensuring maximum energy efficiency and comfort. Warranty coverage on piping materials also plays a significant role in long-term system reliability.

| Factor | Importance | Impact on System |

| Flexible Fittings | Facilitates installation in complex layouts | Enhances system adaptability |

| Heating System Controls | Regulates temperature for comfort | Improves energy efficiency |

| Pipe Insulation | Reduces heat loss | Increases overall efficacy |

| Bore Sizing | Ensures optimal flow rates | Affects heating performance |

Key Factors to Consider When Choosing UFH Pipes

Selecting the appropriate underfloor heating (UFH) pipes is crucial for optimizing system performance and longevity. Key factors include pipe durability, as materials must withstand thermal expansion and pressures without degradation.

- Heat conductivity is crucial for efficient heat distribution; materials like PERT and PERT-AL-PERT offer superior conductivity.

- Installation practices significantly impact overall effectiveness; proper spacing and fitting reduce future maintenance issues.

- The inclusion of expansion joints accommodates thermal movement, preventing stress on the system.

- Additionally, cost trade-offs must be evaluated; while higher-quality materials may incur initial expenses, their longevity and performance can justify the investment.

An analytical approach to these factors ensures the selection of UFH pipes that meet specific project requirements, enhancing both efficiency and sustainability.

Types of Pipes for Underfloor Heating

Underfloor heating systems utilize various types of pipes, each with distinct characteristics and applications. PERT and PEX are recognized for their thermal resistance and flexibility, while PPR serves as a durable alternative. Additionally, multilayer composite pipes, such as PERT-AL-PERT and PEX-AL-PEX, combine the benefits of different materials to optimize heat distribution and resistance to oxygen permeation.

PERT (Polyethylene of Raised Temperature Resistance)

How does PERT (Polyethylene of Raised Temperature Resistance) differ from other piping materials in underfloor heating systems? PERT exhibits superior thermal conductivity, rated at 0.45 W/mK, which enhances efficiency in heat distribution compared to alternatives.

This flexibility facilitates installation in complex layouts, integrating seamlessly with systems utilizing recycled gravel or solar integration technologies. Furthermore, PERT accommodates modern controls such as wireless thermostats, optimizing energy use. Its compatibility with acoustic insulation enhances soundproofing in environments where a radiant ceiling is present.

| Property | PERT |

| Thermal Conductivity | 0.45 W/mK |

| Flexibility | High |

| Temperature Range | -40°C to +95°C |

| Pressure Rating | Up to 6 bar at 70°C |

| Application | UFH, Radiator, Potable Water |

PEX (Cross-linked Polyethylene)

What distinguishes PEX (Cross-linked Polyethylene) pipes from other materials in underfloor heating applications is their unique structural properties and performance characteristics. PEX pipes exhibit high resistance to temperature fluctuations and mechanical stress, making them suitable for diverse applications, including reclaimed water systems and medical devices. Their flexibility facilitates installation in complex environments, such as those involving high pressure gas or underwater pipelines. Moreover, PEX’s ability to withstand extreme conditions renders it viable for use in explosive environments, where safety and reliability are paramount. The cross-linking process enhances thermal stability and durability, ensuring longevity in underfloor heating systems, thereby positioning PEX as a superior choice among polymeric piping materials.

Multilayer Composite Pipes (PERT-AL-PERT, PEX-AL-PEX)

When considering the optimal piping solutions for underfloor heating systems, multilayer composite pipes such as PERT-AL-PERT and PEX-AL-PEX emerge as advanced options that combine the benefits of various materials. These pipes feature an inner and outer layer of polyethylene fused with an aluminum core, providing excellent thermal performance and durability. Compliance with building codes ensures that installations meet safety and efficiency standards, while policies promoting solar integration enhance their appeal in sustainable designs. Additionally, the adaptability of multilayer pipes allows for innovative applications, such as fiber optic routing for smart thermostats, optimizing energy management. The unique characteristics of these pipes position them as a superior choice for underfloor heating systems.

PE-RT vs PEX: A Direct Comparison

How do PE-RT and PEX compare in terms of performance and application within underfloor heating systems? Both materials exhibit distinct advantages, making them suitable for diverse applications.

- Thermal Conductivity: PE-RT offers superior thermal conductivity(0.45 W/mK), enhancing heating efficiency compared to PEX (0.35 W/mK).

- Flexibility and Installation: PE-RT’s flexibility facilitates easier drilling alignment during installation, while PEX’s color coding aids in system identification.

- Durability and Warranty Terms: PE-RT generally provides extended warranty terms and better axle load resistance, while PEX offers more recycling options post-use.

Ultimately, the choice between PE-RT and PEX hinges on specific project requirements and long-term performance expectations within underfloor heating systems.

Installation and Layout Best Practices

When considering the installation and layout of underfloor heating (UFH) systems, attention to detail is important for achieving ideal performance and efficiency.

Employing eco-friendly materials can enhance sustainability while ensuring durability.

Pipe installation precision is paramount; improper spacing can lead to uneven heating.

Moreover, integration with curb appeal must be considered, as the layout affects visible aesthetics.

Sound insulation impact should also be assessed, as UFH systems can transmit noise without proper measures.

Outdoor UFH challenges, such as temperature fluctuations and moisture exposure, necessitate robust planning and material selection.

Comparative Table of Pipe Options

The effectiveness of underfloor heating (UFH) systems is considerably influenced by the choice of piping material, which directly correlates with performance, durability, and installation efficiency. Understanding the comparative advantages of various pipes aids in optimize system design while considering topic relevance. Key factors include:

- Material Durability: PEX-aoffers superior longevity and flexibility, while Polybutylene is less durable at high temperatures.

- Installation Ease: PERT and PERT-AL-PERTprovide enhanced flexibility, simplifying installation in complex layouts.

- Cost Efficiency & Environmental Impact: PEX-cis budget-friendly yet requires careful handling, balancing cost with environmental considerations.

This comparative analysis ensures that stakeholders make informed decisions that support optimal system performance and sustainability.

Riifo’s Recommended Solutions

What strategies can enhance the reliability and convenience of underfloor heating systems for consumers? Riifo’s recommended solutions emphasize long-term product reliability through a robust 25-year warranty, underscoring the manufacturer’s commitment to quality and customer satisfaction. Additionally, the inclusion of product liability insurance provides essential coverage, safeguarding clients’ legal rights. Riifo’s local warehouse facilitates convenient pickup options, minimizing wait times and enhancing the overall customer experience. With a strong North America focus, these offerings align with regional logistics and effectively address customer needs. Collectively, these core benefits not only improve system reliability but also establish a foundation for consumer confidence in underfloor heating solutions, ensuring both peace of mind and superior performance.

Frequently Asked Questions

What Is the Lifespan of Different Underfloor Heating Pipes?

The pipe lifespan varies significantly among materials; PEX typically lasts 25-50 years, while PERT and PERT-AL-PERT offer similar durability. Understanding failure modes and planning replacements ensures effective lifetime comparison and maintenance of underfloor heating systems.

Can I Use Recycled Materials for UFH Pipes?

Recycled materials such as recycled plastics, reclaimed metals, and salvaged fibers can theoretically be used for underfloor heating pipes, though their long-term reliability and thermal efficiency require careful evaluation against industry standards and performance expectations.

How Do Temperature Fluctuations Affect Pipe Choice?

Temperature fluctuations necessitate a careful selection of piping materials, emphasizing temperature stability, material expansion, and compression resistance. These factors influence thermal cycling and joint integrity, ultimately determining the system’s long-term performance and reliability.

Are There Environmental Impacts Associated With Pipe Production?

Pipe manufacturing entails significant environmental impacts, including elevated energy use, substantial emissions, and resource depletion. These factors warrant careful consideration, as they influence the sustainability of underfloor heating systems and the broader ecological footprint associated with their production.

What Maintenance Is Required for UFH Pipe Systems?

Regular maintenance checks are essential for UFH pipe systems, focusing on leak prevention, expansion joints, insulation considerations, and corrosion testing. These measures ensure optimal performance, longevity, and efficient heat distribution throughout the heating system.

Conclusion

In conclusion, selecting the appropriate piping material for underfloor heating systems is essential for maximizing efficiency and longevity. By understanding the unique characteristics of each option, homeowners and professionals can make informed choices that enhance performance. Whether prioritizing flexibility, thermal conductivity, or cost-effectiveness, the right material lays the foundation for comfort and reliability. Ultimately, a well-informed decision ensures not only optimal heating but also peace of mind, transforming spaces into warm, inviting environments for years to come.