When installing a multilayer plumbing system, compliance with AS/NZS5601.1:2024 is crucial. Installers must consider wall exit distances, ensuring at least one metre of metallic piping before exiting walls. Proper jointing techniques, temperature, and pressure limits must be strictly adhered to for system integrity. Additionally, careful handling and compatibility of materials are essential to avoid failures. Understanding these factors paves the way for a reliable installation and further insights into best practices and common pitfalls await.

Key Takeaways

- Ensure compliance with AS/NZS5601.1:2024 for materials, installation, and safety regulations to avoid legal repercussions.

- Maintain at least one metre of metallic piping before wall exits and ensure clearances from appliances to prevent heat safety issues.

- Utilize certified components for all connections and terminations to guarantee system reliability and performance.

- Follow strict temperature (max 95°C) and pressure (max 1.6 MPa) guidelines to prevent deformation and ensure system integrity.

- Verify material compatibility and corrosion resistance to enhance overall system performance and durability.

Introduction

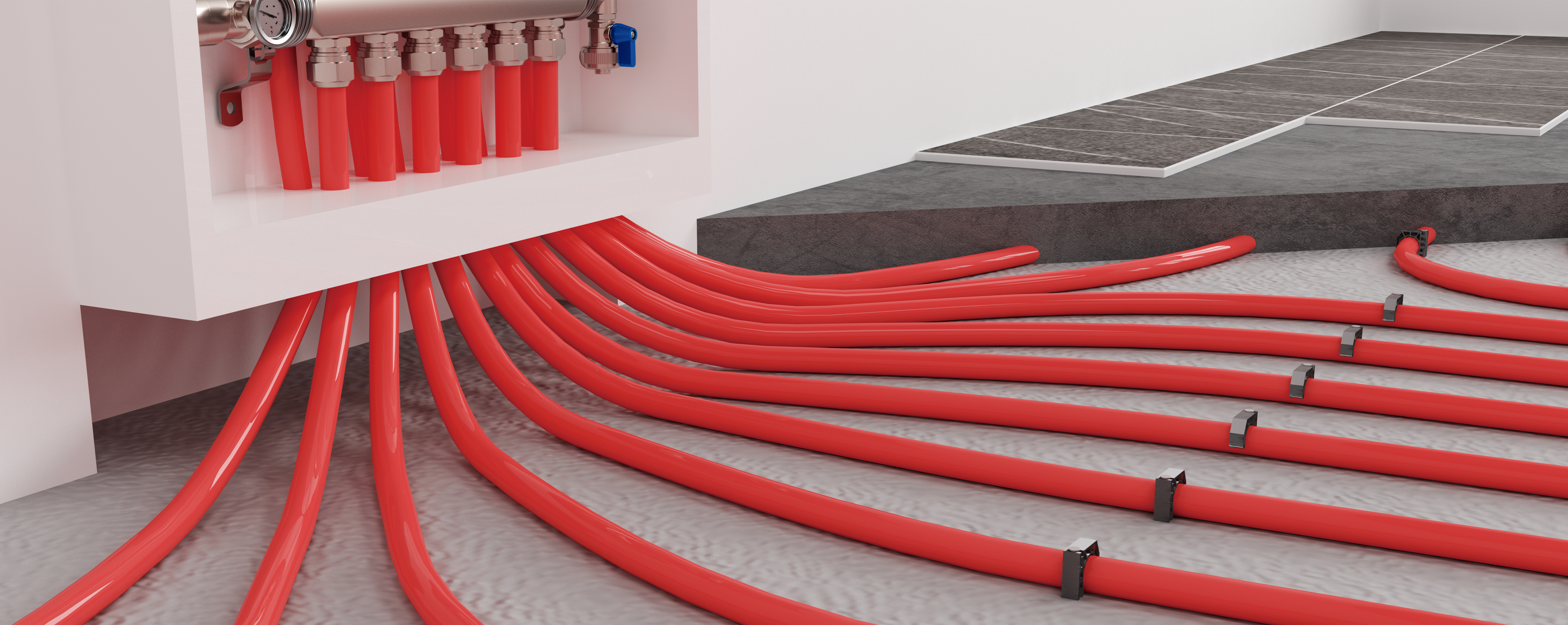

The increasing adoption of multilayer (PEX-AL-PEX) pipes in plumbing systems is attributed to their unique combination of metal strength and plastic flexibility. This innovative design enhances durability while providing resistance to deformation and corrosion, making it a preferred choice for various applications. Understanding the implications of this material’s properties is essential for ensuring effective installation and long-term performance.

Growing popularity of multilayer (PEX-AL-PEX) pipes in plumbing

Why are multilayer (PEX-AL-PEX) pipes gaining traction in contemporary plumbing systems? The multilayer benefits of these pipes stem from their unique construction, which features an aluminum layer sandwicwiched between two plastic layers. This design enhances corrosion resistance, significantly extending the lifespan of plumbing systems. Additionally, the aluminum layer mitigates the shape memory of plastic, allowing for improved pressure resilience and stability across various temperature classes. The compatibility of multilayer pipes with specialized installation tools further facilitates efficient assembly and integration into existing systems. As plumbing standards evolve, the adoption of multilayer systems offers a robust solution that combines the flexibility of plastic with the strength of metal, addressing the growing demand for durable and reliable piping solutions.

Balance of metal strength and plastic flexibility

Multilayer pipes, characterized by their unique tri-layer construction, exemplify an effective integration of metal strength and plastic flexibility. The aluminum layer, situated between two plastic layers, enhances structural integrity while providing heat resistance and corrosion protection. This configuration allows multilayer pipes to withstand varying pressures and temperatures, making them suitable for different pipe classes. Furthermore, the combination of materials mitigates the shape memory of plastic, reducing deformation risks. Effective crimping methods ensure secure connections, preserving the integrity of the system. Overall, the balance of metal strength and plastic flexibility in multilayer pipes affords a robust solution for modern plumbing applications, meeting stringent performance requirements while enhancing durability and reliability.

Understanding Multilayer Plumbing Systems

How does a multilayer plumbing system integrate the strengths of various materials to enhance performance? This system features a multilayer composition that combines plastic layers with a central aluminum role, optimizing both flexibility and structural integrity. The unique benefits of this composition include:

- Enhanced corrosion resistancedue to protective plastic layers.

- Improved pressure resilience from the aluminum layer, minimizing deformation.

- A smooth inner surface that reduces pressure drops and maintains water quality.

- A robust classification system that categorizes pipes based on temperature and application suitability.

Pre-Installation Considerations

Pre-installation considerations for multilayer plumbing systems encompass critical factors such as project scope, pipe class selection, and adherence to regulations and standards.

It is essential to identify limitations related to the chosen materials and ensure compatibility with existing systems.

A thorough assessment of these elements is vital for compliance and optimal system performance.

Project scope

When considering the installation of a multilayer plumbing system, it is imperative to define the project scope thoroughly. This involves a meticulous assessment of various factors to ensure compliance and operational efficiency. Key considerations include:

- Metallic requirements: Ensure compliance with specifications for metallic piping prior to wall exits.

- Wall exit distance: Establish termination rulesthat mandate a minimum distance before exiting walls, enhancing safety and performance.

- Appliance proximity: Assess the placement of appliances to meet termination distance regulations and avoid heat damage.

- Certification credentials: Verify that all materials and installations align with relevant standards, including AS/NZS5601.1:2024 compliance.

A well-defined project scope minimizes risks and facilitates successful multilayer plumbing system installations.

Pipe class selection

Selecting the appropriate pipe class is a critical step in the installation of a multilayer plumbing system, influencing both performance and compliance with industry standards. Each class presents distinct characteristics, such as the coefficient of friction and resistance to thermal expansion, which are essential for ensuring efficient fluid flow and system longevity. Additionally, the pipe’s ability to withstand bending without compromising integrity is vital during installation. Chlorine resistance is another key factor, particularly for systems distributing potable water. To ensure structural integrity, dye penetrant tests can be employed to detect any flaws or imperfections. Mastery in pipe class selection ultimately leads to optimal system performance and adherence to regulatory requirements.

Regulations & Standards

What regulations and standards govern the installation of multilayer plumbing systems? Compliance with established codes is essential for ensuring safety and functionality. Key considerations include:

- Multilayer Compatibility: Ensuring all materials meet AS 4176.8 specifications.

- Aluminum Layer Purpose: Recognizing the aluminum layer’s role in enhancing pressure resilience and preventing deformation.

- Heat Dissipation: Adhering to requirements for metallic piping before wall exits to mitigate heat-related issues.

- Termination Clearances: Observing the mandated distance of at least 1 metre from appliances to prevent heat damage.

These regulations are essential for maintaining integrity and performance in multilayer plumbing systems, particularly concerning wall exit requirements and proper installation practices. Compliance ensures a reliable, efficient plumbing infrastructure.

Limitations

How can installers effectively navigate the limitations associated with multilayer plumbing systems during pre-installation? Understanding amendment details, particularly those introduced in AS/NZS 5601.1:2024, is crucial. Installers must comply with wall exit rules, ensuring a minimum of one lineal metre of metallic piping before exiting a wall. This is vital for mitigating heat-related issues. Additionally, appliance distance regulations necessitate that multilayer pipes terminate at least one metre from the nearest appliance, with potential for greater separation based on specific appliance requirements. Non-compliance with these termination requirements can lead to significant consequences, including safety risks and legal repercussions. Therefore, meticulous attention to these limitations is essential for ensuring compliance and optimal system performance.

Compatibility

Navigating the limitations of multilayer plumbing systems requires a thorough understanding of compatibility during pre-installation. Ensuring that all components work harmoniously is essential to achieving optimal performance and longevity. Key considerations include:

- Material Compatibility: Verify that all materials are compatible to minimize chemical reactions and ensure structural integrity.

- Corrosion Resistance: Assess the corrosion resistanceof the multilayer pipes against the fluids they will carry, as this affects durability.

- Pressure Ratings: Confirm that the pressure ratingsof all components align to prevent system failures under operational conditions.

- Thermal Expansion: Account for thermal expansiondifferences between materials, which can affect joint integrity and overall system performance.

Proper installation tools must also be employed to ensure that all connections are secure and reliable.

Installation Requirements for Safety and Compliance

When installing a multilayer plumbing system, adherence to specific installation requirements is crucial for ensuring safety and compliance.

Key considerations include appropriate handling and storage of materials, precise temperature and pressure guidelines, and proper jointing and connection methods to maintain system integrity.

Furthermore, compliance with regulations regarding wall exits and appliance connections is essential to mitigate potential hazards and ensure optimal performance.

Wall Exits & Appliance Connections

To ensure safety and compliance in plumbing installations, the requirements for wall exits and appliance connections must be rigorously adhered to. The following regulations govern installations involving multilayer plumbing systems:

- Metallic Requirements: Before exiting a wall, the consumer piping must consist of at least one lineal meterof metallic material.

- Distance Regulation: Multilayer pipemust terminate at least one meter from the nearest part of any appliance.

- Termination Guidelines: All connections must utilize certified components, ensuring the integrity of the system.

- Installation Compliance: Adherence to manufacturersspecifications is mandatory to avoid non-compliance with AS/NZS 5601.1:2022.

These criteria are essential for safeguarding against potential hazards and ensuring the efficient operation of plumbing systems.

Temperature & Pressure Guidelines

How do temperature and pressure specifications influence the installation of multilayer plumbing systems? Compliance with these guidelines is crucial for ensuring heat resistance and corrosion protection, which directly impacts system longevity. Understanding the tool requirements for installation and the implications of pricing options allows for informed decision-making. Additionally, warranty coverage often hinges on adherence to these specifications.

| Specification | Requirement | Impact |

| Maximum Temperature | 95°C | Prevents deformation |

| Maximum Pressure | 1.6 MPa | Ensures system integrity |

| Minimum Temperature | -20°C | Maintains functionality |

Adhering to these temperature and pressure guidelines ensures optimal performance and compliance with safety standards.

Jointing and Connection Methods

The integrity of multilayer plumbing systems relies heavily on appropriate jointing and connection methods, particularly in relation to safety and compliance. The selection of proper techniques is critical to ensure system reliability and adherence to regulations. Consider the following jointing and connection methods:

- Crimping Techniques: Utilize crimping tools to create secure joints without compromising pipe integrity.

- Hose Assemblies: Implement certified hose assembliesfor flexible connections, particularly near appliance shut-offs.

- Manual Shut-Off Valves: Ensure final connections to appliancesincorporate certified manual shut-off valves.

- Installation Standards: Adhere strictly to manufacturer specificationsand relevant standards to prevent non-compliance.

Failure to apply these methods correctly can result in system failures, safety hazards, and legal repercussions.

Handling & Storage

What essential practices should be adopted for the handling and storage of multilayer plumbing systems to ensure safety and compliance?

Proper handling and storage protocols are critical to maintain the integrity of multilayer pipes. Tools and equipment must be suitable to prevent physical damage during transport. Packaging and labeling should clearly identify the product specifications, guaranteeing compliance with relevant standards. During shipping and receiving, conditions should be monitored to avoid exposure to extreme temperatures or moisture, which can compromise material properties. Bulk ordering should include provisions for safe on-site storage to avoid deformation or contamination. Adherence to these practices not only ensures compliance with industry standards but also enhances the longevity and performance of the multilayer plumbing system.

Best Practices During Installation

When undertaking the installation of a multilayer plumbing system, adherence to established best practices is ensure to guarantee compliance and optimal performance. Key considerations include:

- Follow Installation Guidelines: Ensure compliance with AS/NZS standards, particularly regarding multilayer pipe requirementsand placement.

- Assess Thermal Expansion: Account for thermal movement to prevent stress on connections and maintain system integrity.

- Ensure Corrosion Resistance: Utilize materials and fittings that resist corrosion, enhancing the longevity of the plumbing system.

- Verify Tool Compatibility: Employ appropriate tools for installation to ensure proper fittings and connections, avoiding potential failures.

Common Mistakes to Avoid

How can installers avoid pitfalls that compromise the integrity of multilayer plumbing systems? One common mistake is neglecting multilayer corrosion prevention, particularly by failing to ensure proper heat insulation around connections. Installers must adhere to wall exit constraints; a metallic section of at least one meter is required before exiting a wall. Additionally, improper termination distance—less than one meter from appliances—can lead to heat damage and system failure. Installers should also prioritize the use of certified valve connections to guarantee reliable and safe operation. By addressing these critical areas, installers can significantly enhance the durability and performance of multilayer plumbing systems, ensuring compliance with relevant standards and regulations.

Frequently Asked Questions

Can Multilayer Pipes Be Used for Gas Installations?

Multilayer pipes can be utilized in gas installations, provided they adhere to gas safety protocols, pressure limits, material compatibility, and certification standards. Proper installation practices are essential to guarantee compliance and optimal performance in gas applications.

What Tools Are Needed for Multilayer Pipe Installation?

Like a chef meticulously selecting knives, the installation of multilayer piping requires precise tools: crimping tools, pipe cutters, and gauges. Ensuring material compatibility and connector safety is essential for system maintenance and performance longevity.

How Do I Maintain Multilayer Plumbing Systems?

To maintain multilayer plumbing systems, implement regular service intervals, employ leak detection methods, prioritize corrosion prevention strategies, and monitor for signs of aging. Timely replacement of deteriorating components is essential to ensure system integrity and performance.

Are Multilayer Pipes Suitable for Outdoor Use?

Multilayer pipes exhibit limited suitability for outdoor use due to UV resistance concerns and temperature range limitations. Proper outdoor protection and weatherproofing measures are essential to mitigate potential degradation and ensure long-term performance in exposed environments.

What Are the Cost Implications of Using Multilayer Pipes?

Ironically, while multilayer pipes promise lifecycle savings, hidden cost implications emerge through material pricing, elevated installation costs, and ongoing maintenance expenses. A meticulous analysis reveals that initial investments may yield unexpected long-term financial burdens.

Conclusion

In conclusion, installing a multilayer plumbing system demands meticulous attention to technical standards and best practices to assure safety and compliance. As the adage goes, “An ounce of prevention is worth a pound of cure.” By understanding the intricacies of multilayer pipes, adhering to AS/NZS 5601.1:2024 regulations, and avoiding common installation pitfalls, professionals can safeguard the integrity of plumbing systems while maximizing their performance and longevity. Thorough preparation is essential for a successful installation outcome.